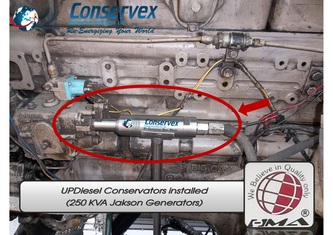

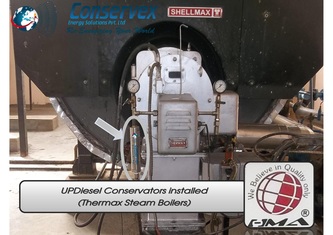

Working principle for fuel conservators in power generators

Principally fuel conservators operate on the base fundamental that if the hydrocarbon fuel is passed under our patented field pattern and specif strength in Conservex fuel Conservators , the ortho hydrogen atoms in the hydrocarbon fuel molecules tends to reverse its poles. This intern temporarily results in effective decrease in inter & intra-molecular forces between hydrocarbon molecules.Thus resulting in complete oxidation of carbon liberating maximum energy . This results in greater thermal efficiency & greater net effective mechanical work.

For advanced IC controlled fuel injection and firing engines , more mechanical work is performed in the combustion engine ,with lesser amount of fuel . This higher mechanical work is delivered to alternator by means of increased RPM. This increased RPM intern is counter balanced by the automatic flywheel or IC to control the injectors to maintain constant unit production , within lesser amount of fuel (Firing modes are automatically maintained by the controller systems to maintain desired RPM) .

As almost complete oxidation of hydrocarbon carbon is achieved by using fuel conservators, the carbon deposition of internal cylinders are minimized to zero . Which effectively reduces frictional forces between the piston & cylinders .Thus frictional heat ,noise & engine vibration levels are reduced up to a great extent. Lesser heating of the mechanical parts results in mimumum wear n tear of mechanical parts.It also reduces contamination of lubricants and minimize rupturing of oil seals due to overheating.

For advanced IC controlled fuel injection and firing engines , more mechanical work is performed in the combustion engine ,with lesser amount of fuel . This higher mechanical work is delivered to alternator by means of increased RPM. This increased RPM intern is counter balanced by the automatic flywheel or IC to control the injectors to maintain constant unit production , within lesser amount of fuel (Firing modes are automatically maintained by the controller systems to maintain desired RPM) .

As almost complete oxidation of hydrocarbon carbon is achieved by using fuel conservators, the carbon deposition of internal cylinders are minimized to zero . Which effectively reduces frictional forces between the piston & cylinders .Thus frictional heat ,noise & engine vibration levels are reduced up to a great extent. Lesser heating of the mechanical parts results in mimumum wear n tear of mechanical parts.It also reduces contamination of lubricants and minimize rupturing of oil seals due to overheating.